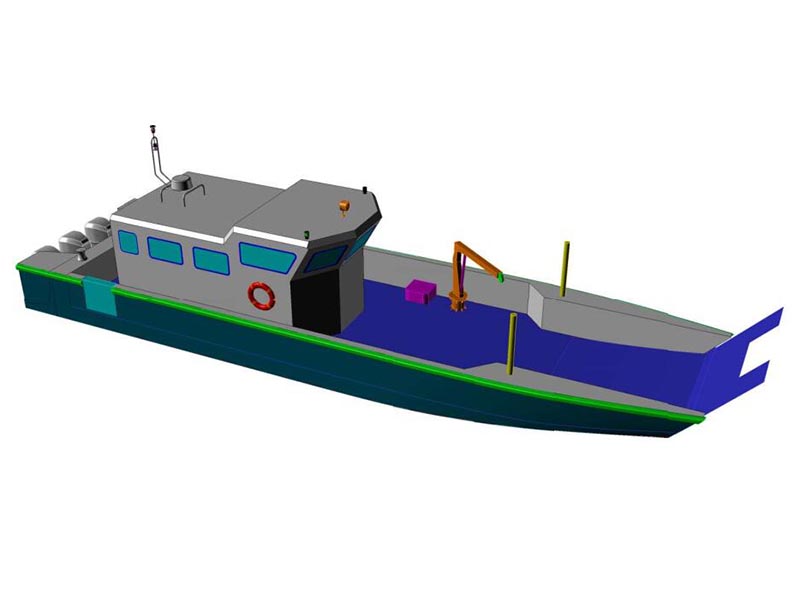

Aluminum Customized Boats Building Process

01

Check the boat design with customer, need to full know customer's requirement then made a scheme plan, scheme plan include:G/A drawing, 3D outside looking, boat description, equipment list,material list.

After checked then make the detail construction drawings.

02

Build the simple female mold according the line chart drawings.

03

Cutting the aluminum plates and other keel, stiffness parts.

04

For the hull, assemble all the parts on the female mold and welding

For the deck or superstructure just welding directly

05

After hull main structure welded ready then turn the hull over, then starting welding hull inside again.

06

Fit main engine and other equipment

07

Decoration cabin and painting

Custom Boats Building Process

01

Build the simple female mold according the line chart drawings.

02

After the male mold ready then painting the gel coat.

03

Painting gelcoat then lamination then Vacuum , make the hull stronger.

04

Fit the keels and RIB in hull

05

Release the deck and hull from male mold then trim the sides

06

Fit the engines, equipments, electronics

07

Water tank test

08

Sea trial

09

Delivery

أكثر من 24 عامًا من الخبرة في بناء السفن.

نحن نبني أكثر من 300 قارب من مختلف الأحجام والأنواع كل عام،

لدينا فريق محترف لتصميم القوارب